In the fast-moving world of the industrial ceramic printing press, it becomes an exercise in eternal vigilance to keep your costs low while maintaining a superior product. This, in essence, means not only producing prints but also figuring out how to manage a complicated production operation in such a way as to conserve every drop of ink, every watt of power. This, of course, includes and starts with an understanding of the particular needs of the substrates you are decorating.

Understanding Your Material and Production Needs

When selecting an industrial ceramic digital printer, it is important to consider the type of ceramics that will be printed, the size and shape of the objects, and the production volume. Other critical factors include print quality, speed, and price.Cost savings start with the right fit. Selecting a printer that isn’t optimized for your specific substrates leads to wasted materials and frequent production halts.

Ceramic materials vary significantly; some are more durable while others are more heat resistant, making it essential to select a printer compatible with your specific material properties. Furthermore, the size and shape of your objects dictate the printer’s hardware requirements. For instance, larger objects require a larger bed size, while complex shapes may need multiple print passes to achieve the desired result. Finally, if you require a high volume of prints, you must choose a machine capable of meeting that demand to avoid production delays or total halts.

- Size & Shape: Does your workflow involve standard flat tiles or complex, 3D shapes? Complex geometries may require multiple print passes or specialized printhead clearance.

- Scale: Are you a boutique studio or a high-volume factory? Choose a machine that scales with your ambition to avoid the “bottleneck effect” where your printer can’t keep up with your kiln.For high-volume factories, the HOLDWIN-3220 is an ideal solution. This Impresora UV features a massive 3200mm x 2000mm printing area, allowing for large-format ceramic slabs or the simultaneous printing of dozens of smaller tiles to avoid production bottlenecks.

Elevating the Artistry of Tiles

The industry is currently seeing a shift in how ceramic tiles are utilized. While modernization once simplified tiles to mere functional floor or bathroom wall coverings, we are now seeing the rise of artistic tiles. Modern consumers are breaking away from conventional uses, seeking designs full of charm that become a central part of home decoration. UV printing for art tiles has become a key technology in this new interpretation of tile art.

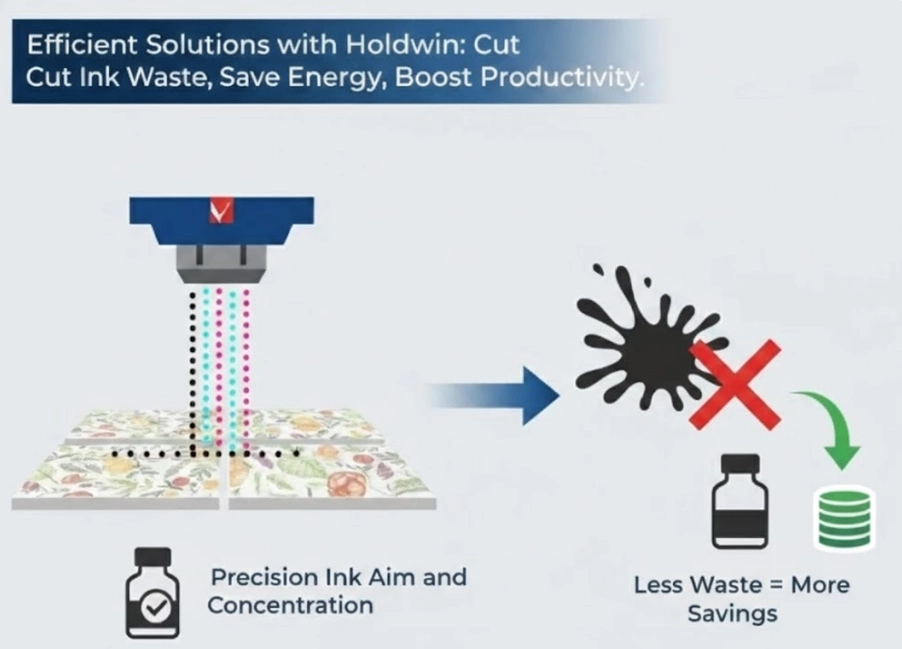

Cutting Down on Ink and Material Waste

The most obvious daily expense is the cost of ink. Modern systems are designed to ensure not a single drop goes to waste. The secret lies in accuracy; high-end printheads ensure each droplet hits the target, stopping messy overspray and reducing the total volume of ink needed. Using high-density inks further allows for rich colors with less liquid, keeping supply costs down over time. Additionally, smart maintenance systems keep printheads clean without flushing away excessive amounts of expensive ink during cleaning cycles.

Maximizing Hardware Efficiency and Power Use

Beyond materials, the machine’s build quality and drying system impact your utility bills. Heaters are often the biggest power hogs; therefore, you need a drying system that works fast and turns off when not needed. A machine built with a heavy, stable frame also saves money by reducing vibrations that wear out small parts.

Streamlining Workflow and Labor

Time is as valuable as ink. Machines that hold multiple printheads finish jobs faster, allowing a smaller team to handle high volumes and cutting labor bills. Smart layout software can “nest” designs closely together, ensuring you use every inch of your substrate and stop throwing away scraps.

Why HOLDWIN Uses UV Printing?

Industrial ceramic printers don’t use “transfers” (DTF/Sublimation) because they add too much cost and labor. HOLDWIN machines print directly onto the tile using UV-curable inks that bond instantly with the surface.

Relying on Professional Support

Choosing a partner like Holdwin ensures your ceramic digital printer operates at peak efficiency. As an industry leader, Holdwin focuses on hardware that transforms struggling shops into high-output success stories. They provide expert technical training and rapid access to high-quality parts, reducing costly downtime. With their professional guidance, your staff can master complex ceramic workflows, minimizing material waste and maximizing your long-term return on investment.

By focusing on these technical and operational areas, you can significantly lower your expenses and keep your ceramic printing business competitive for the long haul.