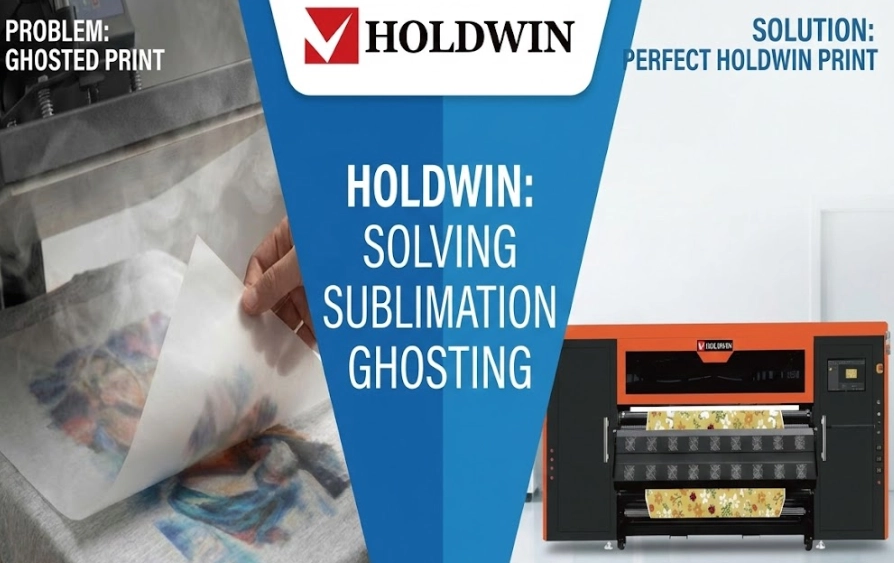

Ghosting is the ultimate frustration in sublimation, turning a crisp design into a blurry mess in seconds. Usually caused by shifting paper or trapped moisture, these “shadows” can ruin your inventory and your profit margins. This HOLDWIN guide breaks down exactly why ghosting happens and how to stop it for good.

What Exactly is Ghosting?

Sublimation ghosting is a printing defect characterized by a faint, blurry shadow or a secondary “ghost” image appearing around the primary design. This phenomenon occurs when the sublimation transfer paper shifts or lifts while the ink is still in its gaseous state during the heat transfer process. Because the ink remains active under high temperatures, any slight movement causes the gas to settle on a secondary location, resulting in a distorted image that compromises the professional quality of the final product.

What Triggers Sublimation Ghosting?

Ghosting pops up when your transfer paper slides just a tiny bit while the ink is still a hot gas. When that paper shifts, the gas lands on a new spot, creating that ugly “shadow” look. While it might seem like bad luck, it usually comes down to three basic things: moving parts, hidden wetness, and wrong pressure.

To get sharp results, you absolutely need a machine that holds everything steady. If you are thinking about getting better gear, the HOLDWIN-1804TX NEW is a fantastic choice. This fast printer is built with great care, making sure every tiny bit of ink hits the right spot. This creates a strong start that makes ghosting much less likely when you finally use the heat press.

The Problem with Moving Paper

The most frequent cause of trouble is the paper moving during the process. This often happens if you yank the heat press lid open too fast. That quick movement creates a sort of wind that sucks the paper up for a split second before it falls back down. Even a tiny shift is enough to make the image look blurry.

To stop this, always use heat-safe tape to lock your design onto the material. If you are working on very large pieces of cloth, you might want to try “sticky” paper. This special paper has a light glue that wakes up when it gets hot, gripping the fabric so the paper simply cannot slide around while you work.

Dealing with Wetness and Humidity

Hidden moisture is the secret enemy of a good print. If your fabric or paper feels even a little damp, that water turns into steam when things get hot. This steam can actually push the paper away or make the ink spread out in a messy way.

A smart trick is to “pre-press” your item for about 5 to 10 seconds before you put the paper on. This quick step bakes out any trapped water and makes the material perfectly flat, creating a dry surface that loves to soak up the ink correctly.

How to Fix Ghosting After It Happens

While it is technically impossible to “undo” the sublimation process once the ink has bonded with the polyester fibers, you can sometimes salvage the item or, at the very least, minimize the visual impact of the error. If the ghosting is faint, you might try re-pressing the item with a clean sheet of parchment paper and a heavy blowout paper to see if some of the excess “ghost” ink can be lifted or faded, though this is rarely a perfect fix. For garments, a creative solution is to re-design the print by adding a larger, darker element or a background pattern that completely covers the shadow. However, the most effective “fix” is often converting the ruined piece into a test substrate; use it to calibrate your heat, pressure, and timing so that your next production run with your HOLDWIN equipment is flawless.

Troubleshooting Quick-Reference

| Symptom | Primary Cause | Solution |

| Shadowed edges | Paper Shifting | Increase use of heat tape/adhesive. |

| Blurry, faded spots | Moisture | Pre-press the item longer. |

| Ink “blooming” | Too much heat/time | Reduce temp by 5° or time by 10s. |

| Double image | Vacuum effect | Open the heat press slowly. |

High-Quality Gear for Perfect Results

Beyond technical expertise, the selection of equipment is a critical factor in minimizing production errors. Holdwin has established itself as a leader in the printing industry, supporting businesses of all scales by seamlessly integrating high-speed performance with premium output quality. Rather than merely providing machinery, Holdwin delivers comprehensive, stable systems engineered to manage high-volume workloads while maintaining the intricate precision required for error-free results. The inclusion of robust metal components minimizes vibration and ensures superior ink distribution, resulting in a consistently professional finish.

Getting the Pressure and Heat Right

If your heat press does not push down hard and even across the whole plate, the ink gas can leak out from the sides. This makes the edges look fuzzy, which people often mistake for ghosting. You should always double-check your tools to make sure there are no cold spots or bent plates that might mess things up.

When the timer hits zero, try to open the press in a slow and smooth way. Instead of ripping the paper off at an odd angle, lift it straight up in one clean move. This stops the “dragging” motion that often causes shadows on the edges of your logos or words.

Get in Touch with Us

Are you ready to stop messing things up and start saving time? Our friendly crew is waiting to discuss your needs and assist you in selecting the best tools for your business. Do you need a little guidance regarding the latest technology in printers, or maybe just a few tips regarding your workspace? We are here to assist you in winning! Contacte-nos via our site or our service branch to begin printing perfect, clear prints every time.