With the current trend of consumption upgrading, the clothing customization market has experienced explosive growth, moving personalized needs—from unique T-shirts for youth to limited-edition hoodies for niche brands—from the margins to the mainstream. However, the traditional industry has long struggled with high costs, low efficiency, and poor printing quality on dark fabrics. HOLDWIN ‘ s dual-station DTG printer shatters traditional customization barriers, using innovative technology to turn industry pain points into high-efficiency solutions for professionals.

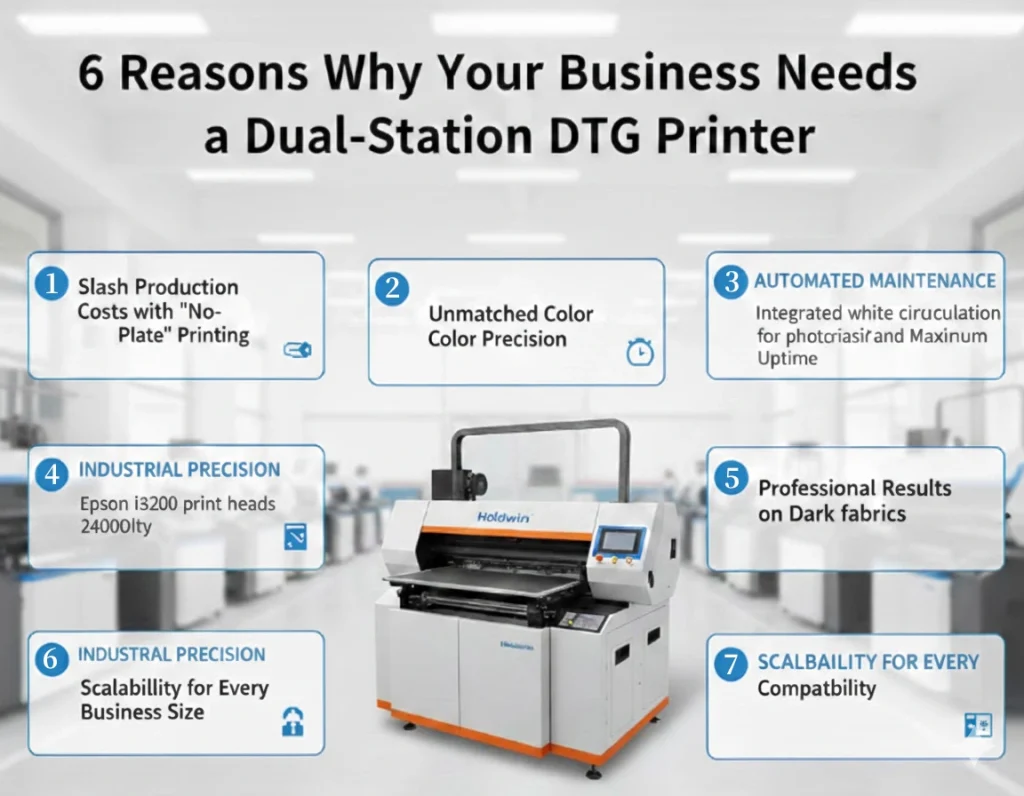

1) Slash Production Costs with “No-Plate” Printing

One of the core advantages of the dual-station DTG direct-to-garment printer is that it completely solves the problem of high costs associated with single-piece customization. Traditional customization often involves multiple complex steps such as plate making, color matching, and printing. These costs are spread across a single product, resulting in high customization prices that deter many consumers and hinder business expansion for retailers.

This dual-station DTG direct-to-garment printer enables “no plate making required, one-click printing” Merchants only need to complete the design on their computer, transfer the file to the device, and it can be printed directly on the garment. Eliminating the high-cost and time-consuming process of plate making not only significantly reduces the cost per piece of customization, making customized clothing more competitively priced, but also shortens the production cycle, allowing consumers to receive their desired products faster.

💡 Related Reading: How HOLDWIN is Disrupting the Apparel Industry with Lower Costs

2) Unmatched Color Precision (9 – Color System)

In traditional printing processes, complex patterns and subtle color gradients are often difficult to reproduce accurately, leading to issues such as color differences and blurry images, which affect the complete presentation of design concepts.

This device utilizes advanced ink jet technology and precise color configuration, supporting 9-color (Y/M/C/K/W/O/R/G/B) printing, enabling highly saturated colors and intricate pattern details to be reproduced with exceptional fidelity. Whether it’s personalized graffiti, lifelike photographs, or richly colored illustrations, everything can be faithfully reproduced on clothing, bringing every creative idea to life. For businesses seeking personalization and differentiation, this is undoubtedly key to enhance product competitiveness.

🎨 Deep Dive: Understanding the CMYK Color Model: A Comprehensive Guide to Color Accuracy

3) Double Your Output with Dual-Station Efficiency

During peak periods of customized orders, businesses no longer need to worry about order backlogs or delivery delays.

Alternating dual-station operation maximizes equipment resources, completing more orders per unit of time, significantly increasing overall productivity, and helping businesses confidently respond to market demands and seize opportunities. Whether it’s small-batch personalized customization or medium-batch order production, this equipment can handle it with ease, creating higher economic benefits for businesses.

4) Automated Maintenance for Maximum Uptime

Traditional DTG struggles with dull white ink on dark fabrics. HOLDWIN ‘ s dual-station printer solves this with professional pre-treatment, ensuring vibrant, high-contrast results every time. To maximize uptime and reduce costs, our system features:

- Advanced Protection: Carriage anti-collision and humidification systems extend printhead life.

- Smart Maintenance: Auto-sleep energy saving and timed self-cleaning prevent clogs.

- Perfect White Ink: Intelligent circulation and stirring eliminate sedimentation for consistent, uniform prints.

🛠️ Pro Tip: Prevent Clogs & Downtime: Our Essential Inkjet Printer Maintenance Guide

5) Professional Results on Dark Fabrics

Before printing on dark-colored clothing, simply spraying with DTG treatment fluid significantly improves the printing effect—white ink becomes brighter and whiter, and colored patterns become more vibrant and saturated. As seen in the sampling of climbing apparel for a client, even a plain black T-shirt, after being printed with this equipment, still exhibits bright colors and clear patterns, completely overturning the traditional impression of poor printing results on dark-colored clothing. to merchants.

6) Scalability for Every Business Size

The introduction of the HOLDWIN dual-station DTG direct-to-garment printer has brought significant energy to the industry. Its many benefits, such as eliminating the need for pattern creation, manageable costs, precise color reproduction, enhanced efficiency, and compatibility with dark colors.

- For Startups : Low entry barriers and fast turnaround for a quick market entry.

- For Enterprises : Enrich product lines and unlock new profit streams with high-end customization.

Conclusion:

If you are also interested in this dual-station DTG direct-to-garment printer and would like to learn more. Let’s join hands with advanced technology, ride the waves in the blue ocean of garment customization, and create more possibilities together!

Frequently Asked Questions:

Standard printers use only Cyan, Magenta, Yellow, and Black, which can struggle to replicate bright oranges, deep greens, or subtle skin tones. By adding specialized inks (like Red, Green, Blue, and Orange), our system covers a much wider color gamut. This results in “true-to-life” prints, smoother gradients, and more vibrant “pop”.

Yes! Printing on dark fabrics used to be a challenge, but our system uses a dedicated white ink station and professional pre-treatment. By applying a base layer of white ink first, the colored design sits on top of the white rather than soaking into the dark fabric.

Not at all. The dual-station design is built for one operator to work more efficiently. While the printer is busy decorating a garment on Station A, the operator can be unloading and reloading Station B. This “alternating” workflow eliminates the idle time.