If you are looking to turn a creative idea into a successful business, Holdwin is here to help you every step of the way. We see ourselves as a helpful partner that gives you the right tools to enter the busy world of custom electronics. We have spent many years making our UV tech better so that you do not have to stress about the small details; instead, you can just focus on your designs. Our gear is built for people who want bright colors, sharp images, and machines that truly last for a long time. Whether you are starting a small shop or running a large factory, our team provides the strong engineering you need to stay ahead. Let’s build a great future together.

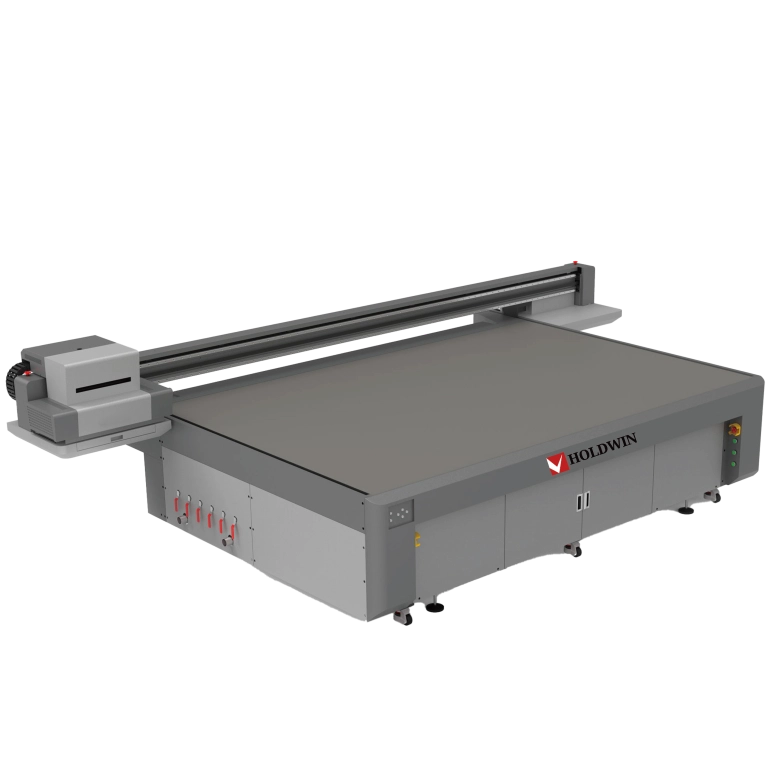

| 🏗️ Featured Model: Learn how to Master Every Market with the HOLDWIN 6090UV, our top-rated machine for high-quality phone case production.

What Is Phone Case Printing?

Phone case printing is the process of applying custom artwork onto protective phone covers using various printing technologies—such as UV printing, sublimation, or direct-to-substrate methods. Each process has pros and cons depending on quality, material, and cost.

Why use Digital UV Printing on Phone Cases?

Custom phone case printing is a thriving market where Digital UV LED technology stands out as the premier choice. By curing ink instantly with light, this process ensures a powerful bond across diverse materials—from soft TPU and leather to hard plastics—without needing expensive pre-coats or lamination.

This technology excels in both quality and efficiency. UV inkjets deliver consistent, vibrant images even on dark or transparent surfaces, allowing for unique 3D textures you can actually feel. Because the prints dry immediately, manufacturers can bypass mounting and drying phases, significantly reducing labor costs and production time.

| 📋 Ultimate Guide: Don’t miss our checklist for choosing a UV printer to ensure you get the best ROI for your small business.

Key Advantages of Custom Phone Case Printing

Cost-Efficient: Prints directly on non-treated materials with no minimum order requirements.

High Performance: Rapid production speeds with unmatched accuracy for complex patterns.

Versatile & Green: An eco-friendly process compatible with almost any substrate.

Picking the Right Phone Cover Printing Machine

The growth of your shop depends on having the right equipment that matches how much you want to sell. Choosing a high-quality phone cover printing machine ensures that your work looks professional and stays the same every time you hit the print button.

For Beginners: The HOLDWIN 6090UV is the industry standard for small shops. Its vacuum bed ensures cases don’t shift during printing.

For Mass Production: The 3220 Model allows you to print hundreds of cases in a single pass, maximizing your hourly profit.

Great Precision for Small Shops

If you are just starting out or have a small boutique, the 6090 UV is a fantastic choice that offers a lot of power in a good size. It comes with a special vacuum bed that sucks the cases down to keep them perfectly flat, ensuring that every tiny detail stays sharp on its 600mm x 900mm surface.

Growing for Larger Needs

When you start getting way more orders, you might need a machine that can handle a bigger load. The 1810 model is built with a larger space so you can print more cases at once without losing any speed. For those who need to make hundreds of items a day, the 3220 model is a giant that lets you fill up a huge table and print everything in one go. These bigger machines use very strong parts to make sure the colors look exactly the same on the first case and the last case, making them perfect for heavy phone case printing jobs.

The Simple Steps to Print a Case

Once you have your new phone cover printing machine ready, following a clear path will help you get the best results without making mistakes.

- Select Suitable Case Material – TPU, PC, silicone, etc.

- Get the Art Ready: Use your computer software to line up your pictures. Clear photos make sure your machine can show every little shade of color.

- Use a Template: Put your cases into a tray or a “jig.” This keeps them from moving around so you can print on many cases at the same time with no errors.

- Jigging is Critical: A proper jig or tray is non-negotiable. For high volume, invest in custom-milled jigs that hold dozens of cases perfectly flat and at a consistent height.

- Print and Dry: The machine puts down the ink and a clear coat while the UV light dries it all at once.

- Final Check: A final inspection under good light is crucial. Check for alignment, color accuracy, and any spots where the ink may not have adhered properly.

| ✨ Explore the Collection: Browse our full range of UV Flatbed and Cylinder printers designed for a variety of rigid materials and cases.

Best Practices for Solving Phone Case Printing Problems

🔹 Color mismatch? Use calibrated profiles and print tests.

🔹 Image alignment issues? Double-check jig placement before printing.

🔹 Cases not fitting? Verify model dimensions before production.

Support You Can Always Count On

Buying a phone cover printing machine is a big step for your business, and you should never feel like you are on your own. Our team is here to help you set everything up and teach you how to use it properly.

If you ever run into a problem, we are available around the clock to help you fix it so you don’t lose any time. From giving you maintenance tips to helping with software, we care about your success because when you do well, we do well.

Get in Touch Today

Are you ready to grow your phone case printing business? Our experts are happy to help you pick the best machine for your budget and your workspace.

See a Sample: Message us to see how great our prints look in person.

Absolutely. The global phone case market is projected to reach over $12.27 billion in 2026 and continue growing. With smartphone adoption exceeding 85% globally and users replacing their devices every 2–3 years, the demand for protective accessories remains constant.

- Polycarbonate (PC): A hard, rigid plastic known for its crystal-clear transparency and high impact resistance. It is perfect for “slim” cases but can crack under extreme stress.

2. Thermoplastic Polyurethane (TPU): A “hybrid” material that blends the toughness of plastic with the flexibility of rubber. It is the most popular choice for modern cases due to its shock absorption.

3. Silicone: A soft, rubber-like polymer that provides a premium “soft-touch” feel and excellent grip

TPU is the clear winner.

Enhanced Protection: It boasts superior abrasion resistance and ‘shape memory,’ ensuring it won’t stretch or become loose over time like silicone does.

Improved Aesthetics: TPU offers high transparency and a glossy finish, in contrast to silicone, which is generally opaque and matte.